In the early 80's a friend and I had the chance to operate on a large club layout in Des Moines. They had a Crow's nest where the dispatchers worked from and we were granted the opportunity to run a local and make some set outs.

That's all it took to get me hooked!

I knew that when I finally got a layout up and running I wanted to have a layout that was based on operations, not just "Roundy Rounds".

Over the years I have looked into several forms of car routing. The first was a computer generated program called "Ship It!" I also thought about using the Car Card system as well as the DOT system [that makes use of the colored dots that are stuck on the roofs of the cars].

When I finally got the layout to a point where I started to think about how to operate it, a few things had changed. My eyes for the most part.

The issues that concerned me with these car routing systems were:

The Ship It program and the Car Card system relied on the actual car number, which in N scale seems to be the biggest complaint "It's too small to see the numbers". If you weather your cars, it can make it even more difficult to see them. Another drawback, you couldn't have duplicate car numbers as it might add a little confusion from time to time.

Both Ship It and the Car Card system require a fairly rigid control and placement of the cars. Should a car get moved off the layout for repairs, or is not placed back in the same location before the next operating session, it can mess with the system. However, Ship It has a way to TRACK a car and knows where is should be, while the Car Card system you can just move the matching card when the car is moved. Not having ever really played with them enough to know for sure, I decided it might more trouble than what I wanted to mess with.

The Dot system, while it seemed easy enough to work, never really appealed to me as it has a tendency in my mind to ruin the overall LOOK of the layout. Nice scenery, weathered cars and locomotives and then here are brightly colored dots moving around the layout on top of the cars. I didn't think this was for me either.

Then a friend came across a system called the "Wheel Report".

The system uses no waybills, car cards, or computer generated switch lists. It's basically made up using a simple printed spread sheet that is filled out by hand. Being somewhat of an Excel junky and seeing how Excel could automate it, we started designing it.

We based the method closely to how it is described in an article by Jim Hediger published in the May 1984 Model Railroader with a few variations that fit my needs and layout.

This form, called the "Wheel Report" is then used to govern the car movement during each operating session. On a prototype railroad, a Wheel Report is a list of cars in a train showing destination, weight, load or empty status, etc. for each car, which the conductor updates as the train picks up and sets out cars en route and gives the location for the spotting of each car.

My Wheel Report has this combined into one simple sheet per train or switch job. It has a list of car types across the top and the towns with each industry down the left side. The value at the intersection of each row and column specifies how many of each type of car that is to be spotted at each industry at the towns along the line. Instead of using the actual car numbers, this method relies on just the type of car. So it is up to the Yardmaster to choose the type of car from the pool rather than a specific car number.

These are filled out randomly before each session. I had planned to use dice to randomly choose the amount of cars that needed to be set out but my friend then showed me a handy little random number generator at RANDOM.ORG. You just plug the minimum and maximum number of cars that each siding can hold and click "Generate"

Update 07/22/13

Steven gave me the ability to bring up the file and press F9 which automatically fills in the cars that will be requested per session without having to go through the entire list and manually fill in each industry's need with Random.org.

Instead of having two identical sheets, one for each direction of travel like Jim Hediger used on his Ohio Southern. I use only one sheet for each train as my locals make an "Out and Back" run starting from the yard at El Dorado. This makes things a little easier as you only need to worry about trailing point turnouts during the run with no need of any "Run-arounds" or complicated movements [for the newbie's to worry about].

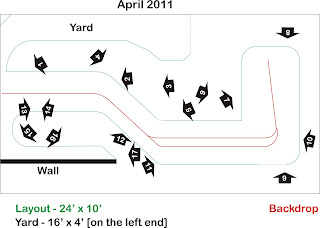

I've set the train length for the locals to be a maximum of 15 cars [average length - 50'], at least two locos and a caboose. The sidings at Dubach, LA and MQ siding [between Calion, AR & Fordyce, AR] were designed to fit this requirement. I left enough room to fudge if needed.

***

On the Ohio Southern's Wheel Report, it states that whatever amount of cars get set out per siding, then the same number of cars needs to be picked up. Thus keeping the train lengths the same and ensures that the train will fit into all the sidings. My Wheel report also shows only the cars that are needed to be set out and not what needs to be pick up.

For my needs I have changed this a little. If a siding can hold three cars max and that industry called for only two cars to be set out, but there are already three cars on the siding, the crews can choose how many cars to be picked up: 2 cars or all 3 cars. The crews of course will have to do a little math and make a quick count to make sure they will still be able to fit into the sidings.

Another way that my Wheel Report differs is that I have multiple sheets that get printed for each train and switch job per session. This is where the use of Excel comes into play. The sheets for all three of the turns: Winnfield, Haskell and the W&OV, are where I input all the cars called for that session using the random number generator.

This information placed on these lists are then cascaded down by Excel and populates the other lists with the proper info. This includes:

The Yardmaster list

The four Manifest lists

The Blocking list for El Dorado

The Winnfield & Haskell turns

The W&OV turn

The Switch jobs for the ICG and Riceland

and the Blocking list for El Dorado yard.

***

On the Ohio Southern, eleven pairs of Wheel Reports were made up, each with a different day numbered 1 through 11. Depending on which day of the month the session was run on, he would pull that days wheel report. If they ran on the 21st of the month, then he would do a little math like this: He would add the two digits of that day 21: 2+1=3 and then would pull out the third day's session. On the 29: 2+9=11, ect. ect.

Once each session of mine gets filled out, I can save them as a file and they can be re-used for another session later, or I can continue to generate a new list for each new session.

Another thing where Excel came in handy is when an odd number of cars are called for El Dorado. Excel adds up the total amount of cars called for each local and then divides them in half and sends half of the cars on the LRMP's and the other half on the MPLR's. This works good until an ODD number of cars are called for. Since you can't send "Half a car" on both trains, Excel uses a True/False statement that is based on the "Day" that's listed on each sheet. Depending if the DAY is odd or even will depend which train gets the ODD car added.

This also gives a nice variation in train length for each session.

***

All said, there are eleven sheets to print for each session.

The Yardmaster uses the Yardmaster's list at the main yard to pre-stage the four manifests that will feed the yard at El Dorado. This list shows how many and what types of cars are needed for the four manifests, the running sequence of the four manifests and the location of the cars in each manifest that will be dropped off at El Dorado.

Once the Yardmaster has the trains made up and ready to go, The Wheel Reports are handed to the crews who are on duty.

The symbols stand for:

Little Rock - Missouri Pacific

Missouri Pacific - Little Rock

The "W" indicates that these trains will deliver the cars needed for the Winnfield & W&OV turns.

The "H" indicates that these trains will deliver the cars for the Haskell turn.

The SB LRMP-W

The NB MPLR-W

The Blocking for El Dorado

The Yard crew at El Dorado uses this sheet to bring all of the cars together to make up the two locals as well as the cars needed for the W&OV.

When the El Dorado crew has the locals ready to pull, the Wheel Reports are then handed over to the local crews and they proceed to make the runs, setting out the cars at the industries along the route.

The Malvern Job/Turn

The Malvern list is used by the W&OV crew to gather the cars from their industries at Malvern at the beginning of each session. After they build their train [called the Razorback] they will deliver them down to El Dorado and exchange them for the new cars listed on this sheet. Once the Razorback returns to Malvern, the local crew will use this list to commence dispersing the newly delivered cars.

The last two sheets are used for the ICG interchange and the Riceland switcher. These sheets simply show what and how many cars are needed to be pulled and spotted for the locals when they arrive at each location. These are performed at the beginning of each session while the locals are being built in El Dorado.

The ICG Interchange

The Riceland Job

Each of the sessions is independent from other sessions. This means the cars do not track from session to session. At the beginning of each session the cars that were picked up from the last session are then returned to the main yard via the four manifests and thrown back into the pool for the next session.

The nice thing about this system is if a car gets misplaced or shipped on the wrong train or to the wrong industry it doesn't really effect the current session or following sessions.

Also if a green crew is running a local and just wants to run the train and not make any set outs or makes a wrong set out, again, it has no cascading effects on future sessions.

The scheduling for all the working trains is still being worked out at this time.

All the through trains that are staged in the main yard are run at random intervals with no specific schedule for now with the exception of a SB reefer train. It needs to drop off livestock cars at Flappers in Fordyce before the Haskell turn makes it's run. Once they have been unloaded, then Haskell turn can pick them up on its way back to El Dorado.

The longest siding on the layout is the passing siding at El Dorado; this siding determined the length of all the through trains. Any meets of the through trains that are needed will be made here. This is also the only scheduled stop for the NB Amtrak. This also forces the locals to take the other four sidings on the main when a through train approaches.

Since the entire layout is dark territory, trains run by a verbal track warrant [which is still being worked out]. The hottest trains on the line are the SB Reefer train and the NB Amtrak, all other through trains have priority over the locals.

***

Since the layout became operational about three years ago, car routing has been on the front burner. We've tested the routing system that I've described above for three sessions so far. I've had to make several minor adjustments after each session, but nothing major.

The first session went smoother than we had hoped for. The only two problems that arose were 1) We had two cars that got put on the wrong train, which turned out to be operator error.

2) After both the LRMP & MPLR trains dropped off their cars, there were too many cars at El Dorado yard and we had no empty tracks to switch them out with!

Before the second session, I made the following changes that we discussed after the first session and changed the Wheel Report by splitting the LRMP and MPLR trains into four separate trains:

The "W" trains deliver cars called for the Winnfield & W&OV turns.

LRMP-W

MPLR-W

The "H" trains deliver cars called for just the Haskell Turn.

LRMP-H

MPLR-H

The second session [which was nothing more than an abbreviated session to test out the changes] proved to be the answer and the yard crew wasn't sweating bullets trying to figure out how to move the cars so they had room!

The third session went even better. The crew at El Dorado had more than enough room after clearing out some of the cars from the previous session and only having the smaller number of cars to deal with for the Winnfield & W&OV turns.

The other thing that I did was I redesigned and included the Blocking sheet for each session. This gave the El Dorado crew a simplified sheet to follow as it not only shows how to block the locals but also shows what and how many cars are needed for each block.

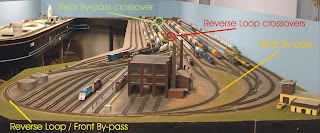

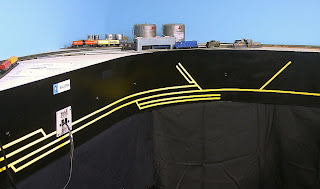

The other major change that I made on the main yard helped out greatly in respect to the flow of traffic. Both the four manifests as well as all the staged through trains can move in and out of the yard without tying up any of the tracks. These changes can be seen on this post: Redesign Of The Main Yard

While this may not be a prototypical car routing system, it seems to work and keeps us happy while playing trains.

Thanks for reading!